Defining Safety Excellence: What Does Great Look Like?

If it isn't clear to executive leadership what it would look like when successful, expect misalignment throughout the rest of the organization.

If safety excellence isn't clearly defined and aligned throughout an organization, it won't be achieved. Ask 10 people to define safety excellence and, on average, you'll get eight distinctly different answers. Ask these same individuals, "What would you see that is common when visiting a work area that would explain why and how safety excellence was achieved?" You'll get 10 different answers.

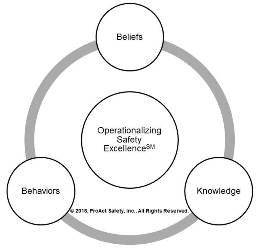

When working with executive leaders in the creation of their three to five year safety excellence strategy, we often begin by determining the existing alignment between different leadership levels. A survey is a frequently used tool to gain this insight, beginning with the two aforementioned questions. Answers range from "no injuries" to very descriptive, well thought-out descriptions of what practices, beliefs, and knowledge would be common that would indicate success. If it isn't clear to executive leadership what it would look like when successful, expect misalignment throughout the rest of the organization. Herein lies the importance of Operationalizing Safety ExcellenceSM.

Safety excellence must be described in operational terms and make sense to the audience whose behaviors you are trying to influence. Safety excellence is more than just repeating great results. It is also profound insight into how the results were obtained, with a shared mindset throughout the culture that continuous improvement will always be possible. Once great results are achieved, what beliefs, knowledge, and behaviors would be common that explains why and creates confidence that the results are more than luck, normal variation, or Hawthorne effect? Below are some examples from recent client engagements that ranged in maturity in their safety performance, culture, and systems.

Beliefs

I believe [company] cares about me and I matter.

I have the right competencies to do the job safely and effectively.

I am trusted, can make informed decisions, and will be supported by management.

Through planning and proper execution, operations are efficient and incident-free.

There is clear and concise communication between all groups.

Knowledge

Details are shared about recent events and what could have prevented them.

I know how to become involved in current safety activities, teams, and committees.

The big and common/routine risks that will be faced at work that day are known.

I know what precautions are required and which ones are discretionary and most desired.

Individuals understand expectations and their job- and safety-specific roles and responsibilities.

I know who to go to and what programs/processes to leverage with concerns and suggestions.

Behaviors and Common Practice

We regularly take the required and most important discretionary precautions.

Job planning and preparation with day-to-day specific tasks is evident.

Better housekeeping: Hazards are identified and corrected immediately.

Proper tools, equipment, and PPE are used correctly and consistently.

Witnessing mentoring and coaching where good safety attitudes and behaviors are nurtured, and there is positive reinforcement of desired safety behavior and safety leadership.

Visual management: Performance boards/5S/visibility of safety team and maintenance efforts and successes; clear goals and targets are able to be identified.

To operationalize safety excellence in your environment, begin dialogue with these important questions. How should safety excellence be defined in our work? What would explain why our performance has either improved or slipped? Once great results are achieved, what beliefs would be common? What would everyone know? What common practices would we observe?

Answers will differ for each company and location. Involve your leaders in answering these questions. It will be time well spent and will serve as the catalyst needed to achieve breakthrough results in both safety performance and culture.

This article originally appeared in the March 2018 issue of Occupational Health & Safety.